Basic Safety Training (BST)

Course Overview:

Our Fire Awareness Training provides essential knowledge and skills to recognize fire hazards, respond appropriately in an emergency, and understand the basics of fire prevention. This course is designed to empower individuals with the confidence and ability to react quickly and safely in the event of a fire.

Who Should Attend:

All employees and staff members

Safety officers

Facility managers

Contractors and maintenance teams

Course Content:

Introduction to Fire Safety

Understanding Fire Behavior (The Fire Triangle)

Common Causes of Workplace Fires

Fire Prevention Best Practices

Types of Fire Extinguishers and Their Uses

How to Safely Evacuate in the Event of a Fire

The Role of Fire Wardens and Emergency Teams

Basic First Aid for Fire-Related Injuries

Assessment & Certification:

Participants will undergo a short assessment at the end of the training. Successful candidates will receive a Fire Awareness Training Certificate.

Training Method:

Classroom-based theory

Practical demonstrations

Group discussions and scenario-based exercises

Benefits of this Training:

Reduces risk of fire incidents at the workplace

Increases confidence and competence during emergencies

Supports compliance with health and safety regulations

Encourages a safety-first culture among employees

Course Overview:

This Working at Heights training course is designed to equip participants with the essential knowledge and practical skills needed to work safely at height. It covers legal responsibilities, hazard identification, risk control measures, and the correct use of fall protection equipment. The course is offered both for first-time participants (Fresher) and as a Refresher for those renewing their certification.

Who Should Attend:

New employees required to work at heights (Fresher)

Experienced workers needing to renew their competency (Refresher)

Maintenance personnel

Construction workers

Wind turbine technicians

Safety officers and supervisors

Course Content:

Understanding the risks associated with working at heights

Legal requirements and regulatory standards

Fall prevention vs fall protection

Selection, inspection, and use of harnesses and fall arrest systems

Proper use of ladders, scaffolds, and elevated work platforms

Emergency rescue planning and procedures

Practical exercises using fall protection equipment

Safe work practices and hazard control measures

Refresher: Half Day (approx. 3–4 hours)

Assessment & Certification:

Participants will be assessed through a combination of practical and theoretical evaluations. Successful candidates will be awarded a Working at Heights Certificate.

Training Method:

Classroom-based learning

Practical, hands-on exercises

Equipment demonstrations

Scenario-based assessments

Benefits of this Training:

Enhances personal safety and awareness when working at height

Meets employer and regulatory compliance requirements

Reduces the risk of workplace falls and injuries

Builds confidence in using safety gear and systems

Entry Requirements:

Physically fit for practical exercises

For refresher: proof of previous valid Working at Heights certification

Course Overview:

This Manual Handling course teaches participants how to safely lift, move, and handle objects to prevent workplace injuries. It focuses on correct lifting techniques, ergonomic practices, and risk assessment to reduce the chance of musculoskeletal disorders and other manual handling-related injuries.

Who Should Attend:

All employees involved in manual handling tasks

Warehouse and logistics staff

Construction workers

Maintenance and facility teams

Supervisors and safety officers

Course Content:

Introduction to Manual Handling and Workplace Injuries

Understanding the Anatomy of the Spine and Injury Risks

Principles of Safe Lifting and Handling

Ergonomic Techniques for Pushing, Pulling, Lifting, and Carrying

Hazard Identification and Risk Assessment

Use of Mechanical Aids and Proper Equipment

Practical Exercises: Correct Lifting Techniques

Strategies for Minimizing Risk in Manual Handling Tasks

Assessment & Certification:

Participants will complete a short practical and/or written assessment. Successful attendees will receive a Manual Handling Training Certificate.

Training Method:

Classroom-based theory

Practical demonstrations and hands-on practice

Group discussions and real-world examples

Benefits of this Training:

Reduces risk of back and musculoskeletal injuries

Promotes safer handling techniques and awareness

Increases overall workplace efficiency and safety culture

Supports compliance with occupational health and safety regulations

Course Overview:

This First Aid training course prepares participants to confidently respond to a wide range of injuries, medical emergencies, and life-threatening situations. It covers essential lifesaving skills, from CPR to wound management, ensuring quick and effective action when it matters most.

Who Should Attend:

All employees and staff members

Site supervisors and safety officers

Construction, industrial, and wind industry workers

Anyone wishing to learn lifesaving skills

Course Content:

Principles of First Aid and Initial Assessment

Managing Unconscious Casualties (Recovery Position)

CPR Techniques for Adults (and use of AED)

Bleeding and Wound Management

Treatment of Burns, Fractures, and Sprains

Choking Response and Airway Management

Shock, Seizures, and Medical Emergencies (e.g., heart attack, stroke)

First Aid Kits: Contents and Usage

Emergency Scene Management and Communication

Assessment & Certification:

Participants must complete a practical and written assessment. Successful candidates will be awarded a First Aid Training Certificate.

Training Method:

Instructor-led classroom training

Hands-on practical sessions with CPR manikins and first aid equipment

Scenario-based drills and group activities

Benefits of this Training:

Empowers participants to act effectively in emergencies

Enhances workplace health and safety readiness

Reduces response times and improves casualty outcomes

Meets industry health and safety requirements

Basic Technical Training (BTT)

Course Overview:

The BTT Mechanical (BTTM) course is part of the GWO Basic Technical Training program. It teaches you to perform basic mechanical tasks under supervision using proper work procedures and PPE, specifically for wind turbine systems. The module highlights key mechanical systems and components—including gearboxes, brake, yaw, cooling, and lubrication systems—and covers bolted and welded connections, as well as hydraulic tensioning tools, with a focus on safety and proper torque practices.

Learning Outcomes:

Explain the main mechanical components and operation of wind turbines.

Identify mechanical risks and hazards.

Understand bolted and welded joint principles and inspect them.

Use manual tightening and measuring tools correctly.

Use hydraulic torque and tensioning tools.

Describe gearbox functions.

Inspect braking systems.

Inspect yaw, cooling, and lubrication systems.

Course Overview:

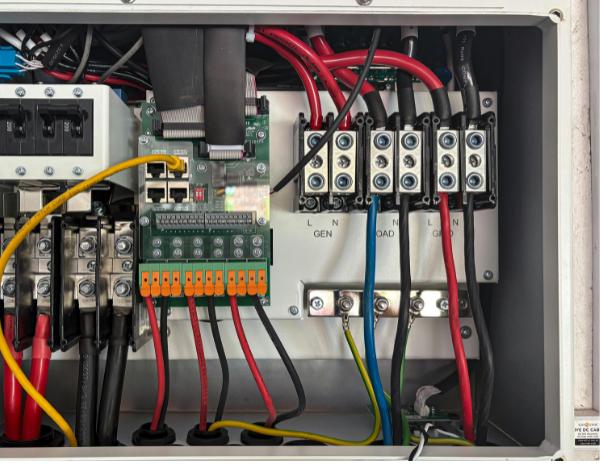

The Electrical (BTTE) course is part of the Basic Technical Training Modules (BTT) required for working in the wind energy sector. This course provides participants with the fundamental skills and knowledge needed to safely work with and troubleshoot basic electrical systems in wind turbines.

Who Should Attend:

New and existing wind turbine technicians

Electrical maintenance workers

Individuals pursuing GWO Basic Technical Training certification

Anyone seeking a career in the renewable energy sector

Course Content:

Introduction to Electrical Concepts (Voltage, Current, Resistance)

Understanding Wind Turbine Electrical Systems and Components

Electrical Symbols, Drawings, and Circuit Diagrams

Safe Isolation Procedures (LOTO – Lockout/Tagout)

Use of Electrical Measurement Tools (Multimeters, Insulation Testers)

Cabling and Connector Types in Turbines

Earthing and Bonding Systems

Basic Fault Finding and Troubleshooting Techniques

Electrical Safety Practices (including PPE and Safe Work Methods)

Assessment & Certification:

Participants will undertake both theoretical and practical assessments. Successful candidates will receive a Electrical (BTTE) Certificate as part of the GWO BTT standard.

Training Method:

Classroom learning with visual aids and interactive discussions

Practical exercises working with real or simulated turbine electrical systems

Hands-on fault-finding tasks

Benefits of this Training:

Provides essential electrical knowledge for working safely in turbines

Prepares for real-world troubleshooting and maintenance tasks

Fulfills part of the GWO Basic Technical Training (BTT) requirement

Improves employability in the growing wind industry.

Course Overview:

The Hydraulics (BTTH) course is part of the GWO Basic Technical Training Modules (BTT) and focuses on the essential knowledge and skills required to safely understand, operate, and maintain hydraulic systems within wind turbines. Participants will learn about hydraulic components, system functions, and basic troubleshooting techniques.

Who Should Attend:

Wind turbine technicians (entry-level and experienced)

Hydraulic maintenance and service personnel

Individuals seeking GWO Basic Technical Training certification

Anyone entering the wind energy industry

Course Content:

Introduction to Hydraulic Systems and Principles (Pressure, Flow, Force)

Hydraulic Components: Pumps, Motors, Valves, Actuators, Reservoirs

Hydraulic Diagrams and Symbol Interpretation

Functions of Hydraulic Systems in Wind Turbines (Yaw, Pitch, Braking Systems)

Safe Handling of Hydraulic Fluids and System Pressure

Basic Preventive Maintenance Tasks

Identification of Common Hydraulic Failures and Troubleshooting

Hydraulic Safety and Environmental Considerations

Assessment & Certification:

Participants must complete both theoretical and practical assessments. Successful candidates will receive a Hydraulics (BTTH) Certificate as part of the GWO BTT qualification.

Training Method:

Classroom-based sessions with visual and practical demonstrations

Hands-on practical exercises using hydraulic training rigs

Group work and case studies

Benefits of this Training:

Develops core competency for working with turbine hydraulic systems

Enhances troubleshooting and preventive maintenance skills

Supports compliance with GWO Basic Technical Training requirements

Increases employability and technical confidence in the wind industry